Florian, optimization engineer

My work keeps me constantly learning and improving my skills. Thanks to this permanent evolution and these stimulating challenges, my experience at Artelys is truly enriching and motivating.

What is your background and role at Artelys?

I’m a graduate of Ensimag, an engineering school in computer science and applied mathematics in Grenoble. I did my third year at the Master of Operations Research, Combinatorics and Optimization at Grenoble Alpes University. I then pursued my thesis at the G-SCOP laboratory, where I worked on star observation scheduling and cutting problems. It was during my thesis that I got to know Artelys, at one of the seminars held at the laboratory.

At the end of my PhD, I applied for a job at Artelys, where I’ve now been working as an optimization engineer for almost 5 years.

My work at Artelys focuses on two main areas: optimization services and solver development.

The service part involves the development of specific solutions for a client’s optimization problem. This includes the design and implementation of optimization solutions. These assignments involve close contact with the customer. One has to understand the client’s problems and needs, and suggest appropriate approaches.

On the solver side, I’m working on the development of the Knitro solver. This is a solver that handles non-linear optimization problems. In particular, I’m working on Knitro’s algorithms for solving mixed-integer nonlinear optimzation problems. My job is to find new ideas for improving the solver’s performance and to implement them. Decisions about improvements are open to discussion. We have the guidelines, then we consider what we think is possible in terms of development time and technical difficulty. We then arbitrate on the priority of solver improvement implementations.

Can you tell us about something you’re working on?

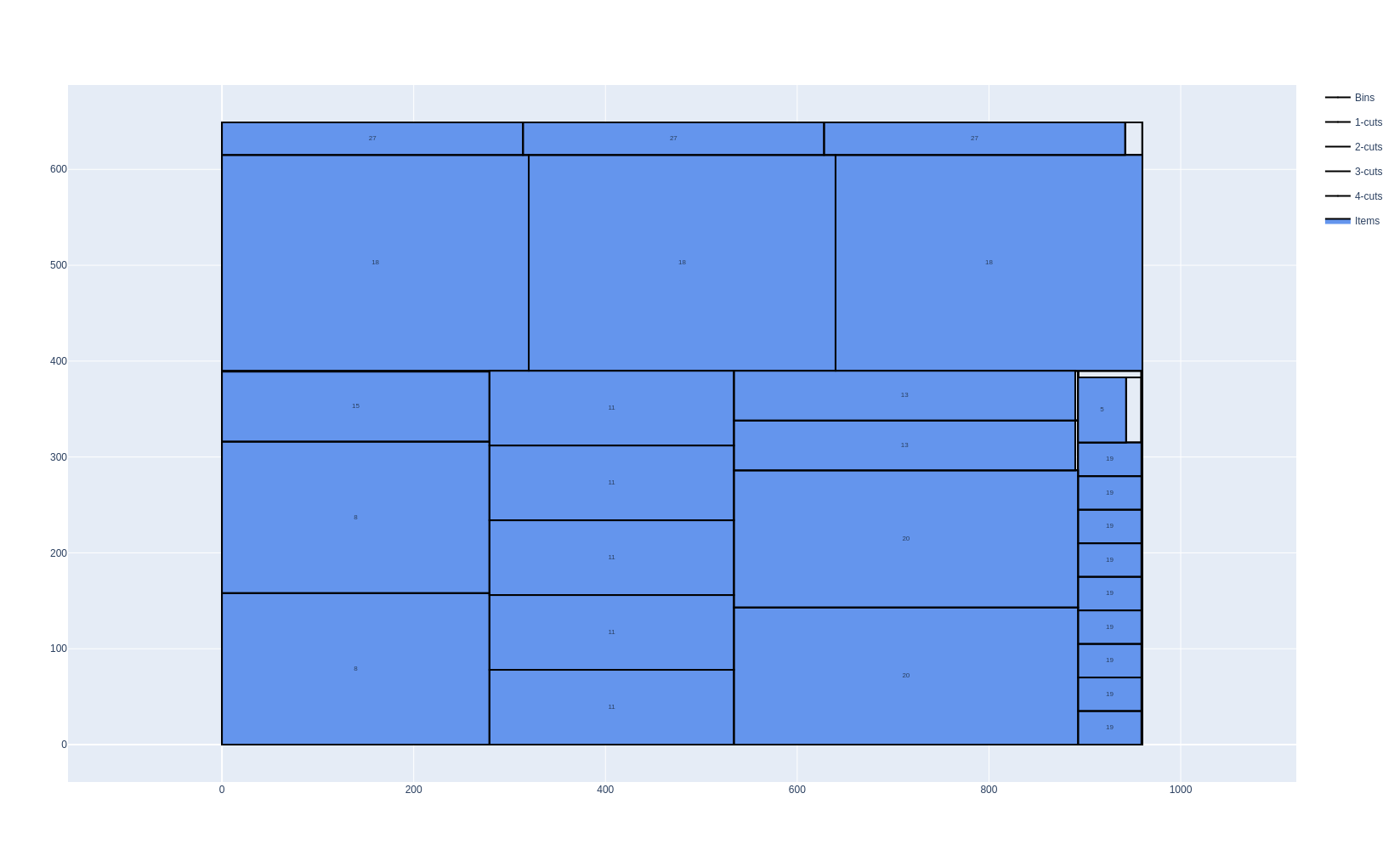

I regularly work on projects related to cutting problems. The aim is to design and implement algorithms which, based on a list of parts to be cut and the materials from which to cut them, generate cutting plans which minimize off-cuts.

These projects are a continuation of part of my thesis work. This allows me to both reuse and deepen the knowledge I acquired during my thesis. It’s also nice to be able to industrialize research work so that it doesn’t just remain in academia, but can have a concrete impact.

These are technically stimulating projects, as industrial problems contain many additional difficulties that need to be managed. This requires a good understanding of methods and thinking.

They are also projects where customer relations go very well, with fluid contact and easy exchanges.

Illustration of cutting problem:

What do you like about your work environment?

First of all, the wide range of applications: cutting optimization as mentioned above, but also other combinatorial packing and scheduling problems, freight transport problems, problems linked to energy production or transport, etc. This enables me to see a diverse range of applications for optimization methods, and to extend my business knowledge in these fields.

Also the diversity of the mathematical tools we use to work on these applications – integer linear programming, constraint programming, tree search, local search, column generation… – depending on what is best suited to the problems to be addressed.

I also appreciate direct contact with the customer on the service side. It’s what allows me to see the real impact of my work, to make sure that what I’m doing is useful and relevant.

Finally, in my work on solvers, I appreciate the technical aspect. We’re working on tools that are state-of-the-art in scientific research, and we’re trying to push them further.

© ARTELYS 2025 • All rights reserved • Legal mentions